Published on 15 June 2021

OPTIMISING MOBILITY FOR DEFENCE VEHICLES

- date 15/06/2021

- lieuLimoges

DESIGN, CONCEPTION, INNOVATION

// STEP 1 : YOUR CONCEPT

The perfect equation : expertise + engineering = success

WHY TEXELIS ?

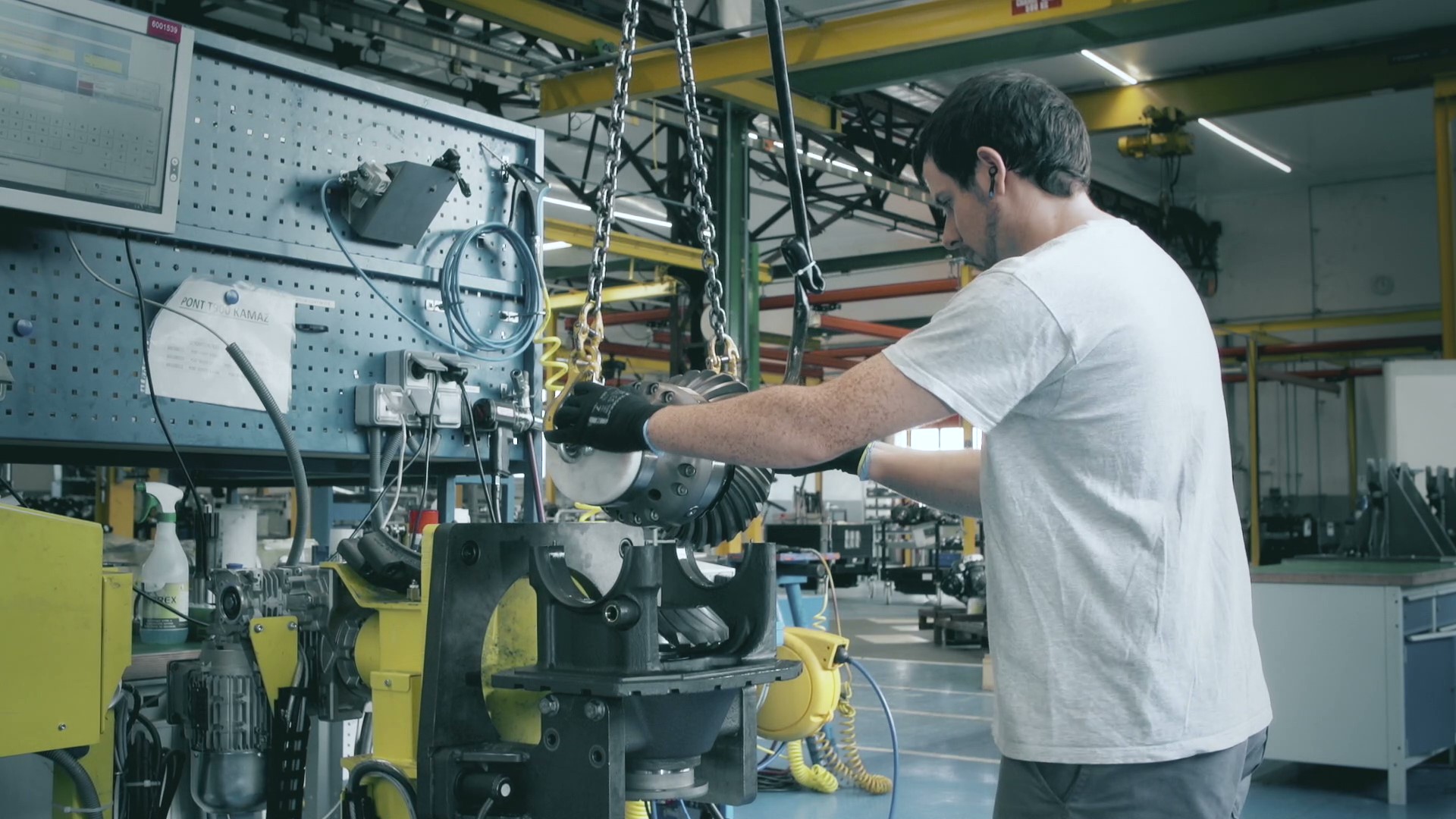

With 80 years’ experience designing and manufacturing axles, drivelines and integrated powertrains for wheeled vehicle applications, TEXELIS is uniquely placed to support the mobility requirements of 4×4, 6×6 and 8×8 military vehicle OEMs.

Our team of engineers have partnered with vehicle manufacturers and military forces across the globe, designing and manufacturing specialist mobility solutions to keep vehicles moving in some of the most extreme terrain on earth. Whether design parameters are lead by extreme power demands, weight restrictions or performance requirements, our team has the deep experience and technical capabilities to exceed customer expectations – whether beginning from a clean sheet design or adapting solutions for existing vehicle upgrades.

By teaming with Texelis for their vehicle mobility requirements, our partners benefit from an understanding of vehicle mobility that is unparalleled in the military vehicle market. From designing bespoke capability as a Tier 1 supplier to the French DGA, to matching vehicle configuration to our select range of engineered products, our solutions deliver safety, reliability and technical superiority to keep military vehicles moving today, tomorrow and beyond.

Bespoke design excellence

TEXELIS designed trailer arms for the Serval (Light VBMR) which make it possible to free up space at the rear of the vehicle, to increase personnel habitability, while maintaining maximum ground clearance. The vehicle is also more easily transportable.

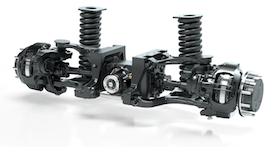

Mobility through experience

TEXELIS’ T700 is an industry renowned product that provides best in class performance and low ownership cost. Designed and manufactured by texelis in cunjunction with Timoney independent suspension technonology.

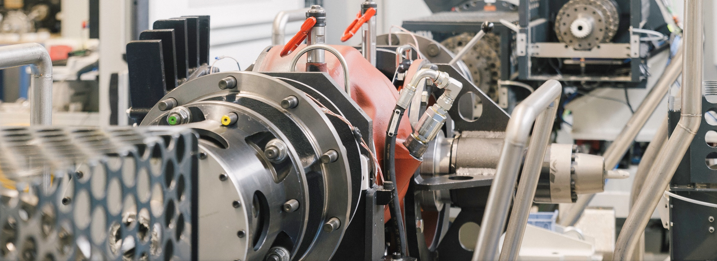

ENGINEERING EXCELLENCE

TEXELIS is a vehicle mobility centre of excellence, with a specialist team of engineers who project manage internal R&D and customer clean sheet design programmes, tailor existing solutions to meet specific design requirements, and are always looking for ways to refine and improve system capability.

The leading design office is fully equipped with high-performance tools including CATIA, Romax, ANSYS and a cutting-edge digital design suite. This allows us to scale management of a large number of projects and ensure a high quality technical service throughout.

We also value agility, and always ensure we have the capacity to work to expedited timescales in line with our customers’ requirements: as shown on the Serval vehicle project, which our team developed in less than two years.

In close collaboration with our partners, we create, manage and share all product technical information at the point of delivery and throughout its projected life-cycle under our tailored Product Lifecycle Management programme.

For example : TEXELIS tailor-made solutions are designed by our in-house design team to meet the exacting requirements of our customers. Designs are refined on-site in our testing and validation centre, with our defence specialists supporting customer testing in the field.

Innovation is a central pillar of our corporate strategy, so we never believe the job is done. We are constantly working to realise tomorrow’s solutions, such as Hybrid Electric solutions.

Our goal is to deliver game-changing technologies that respect the performance, safety and technical requirements of the vehicle.

THE TEXELIS ADVANTAGE

This tireless drive for innovation is the method by which we deliver on our objective: to apply experience, responsiveness and precision to guarantee our customers’ security and success.

Discover the next step in the TEXELIS journey next time, when we discuss the prototype phase…

Latest news

Contact

Send email